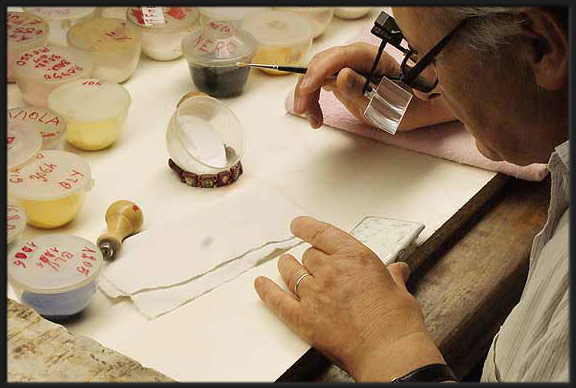

The outercase of a Sillemīs Lighter is first formed than very deep engraved by hand, after this our master made the first step of the enamel. This will be repeated up to seven times.

Modern machines in the manufactur: Laser for producing steal tools and small thinks like hinges and hocks.

Everywhere special tools for the production. Some of the articles need more than 12 differnt tools and elements during the production. They are all exactly desript and well-gromed. We are producing our tools by ourselve, because this machines have a very old tradition and some of them are made in the years 1920.

Meeting of design proposal and first step of production.

..painting of the enamel.

The enamel is ready painted; now careful transport to the oven. Here the enamel melts at nearly 800 degrees and becomes hard like glas after cooling down.

..after painting, melting and cooling the hand of the master is asked again.

..far away from industrial products our mixtures of colors are dokumented and inscript exactly.

..again and again it must bel controlled the right color and transparancy, any single, small fault during the steps could destroy the whole work and all had to start from the beginning.

The final polishing is made with finest powder of chalk and water by hand. After this step the first time the enamel is shining bright and clear. The item is now ready for the last ingraving. The result you will see under Linea Epoque Antique.

A keyring gets the final treatment, the Sillemīs cross will be fixed with fire by hand on the ring

The article gets heated. Only a handfull silversmths are today able to make this by hand in this accuaracy. We are very proud to have them in our production.

Here you see a part of the factory where we are using also modern machines and technic. The galvanik. Also Sterling silver articles get a final bath in the silver-galvanik for highclass results.

..again controlling. By the last polishing of the Sillemīs products the worker looks for perfect surface. . There are great differences on the market and we are using only the best raw silver to get a shiny finish. Other manufactures cover cheap silver plates with quilloche or they satin them.